PP/HDPE Fabric manufacturer

& Supplier in US

Discover our PP/HDPE woven bags, BOPP Bags, Geotextile, and Landscape fabrics, designed for quality and sustainability. Anita Plastics is one-stop solution for reliable packaging and PP/HDPE fabric needs.

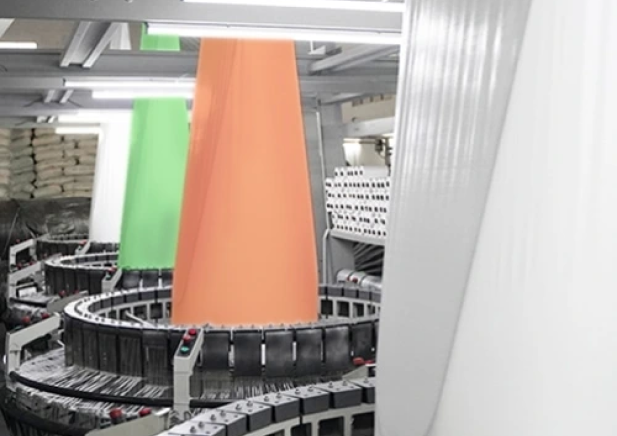

Welcome to Anita Plastics Inc. As a leading polypropylene Fabric manufacturer, we specialize in a wide range of woven Polypropylene / HDPE fabrics, bags, geotextiles. Established in 2005 and based in Solon, Ohio, we’re proud to be the U.S. face of our parent company, the Mewar Group.

Made with the finest machinery and with a strict emphasis for quality, Anita Plastics has grown to become a valued partner for any size of business and offers world-class quality at extremely competitive prices. We sell products solely manufactured by our parent company. Scroll down to learn more about what we can do for you!

Quality You Can Trust

We use the latest machinery and adhere to strict quality standards, ensuring you always

get durable and reliable products.

Competitive Pricing

Get world-class quality without breaking the bank. We offer top-notch products at prices that work for businesses of all sizes.

Why Choose Anita Plastics?

- 42+ Years of Industry Experience

- Serving 17+ Countries

- 13+ Manufacturing Facilities

- 4000+ Tons Per Month Product Capacity

- A Team of Industry Experts

- Cutting-Edge Technology

- Unwavering Commitment to Quality

- Extra Strong

- Water-Resistant

- Multiple Sizes

- Recyclable

Looking for a reliable polypropylene manufacturer and supplier in the US? Contact us now to discuss your specific needs.

Industries We Serve

At Anita Plastics, we offer a range of specialized animal feeding bags designed for cattle, horses, and all pet foods. Our products are crafted with precision to ensure optimal nutrition and care for these animals.

Safety and hygiene take center stage in the food industry. Our high-quality polypropylene bags are perfect for storing and transporting various food items, ensuring they reach consumers in excellent condition.

You need materials that offer strength and corrosion resistance when dealing with chemicals. Our specialized fabrics and bags are designed to contain and safely transport chemical products, meeting the industry’s stringent safety standards.

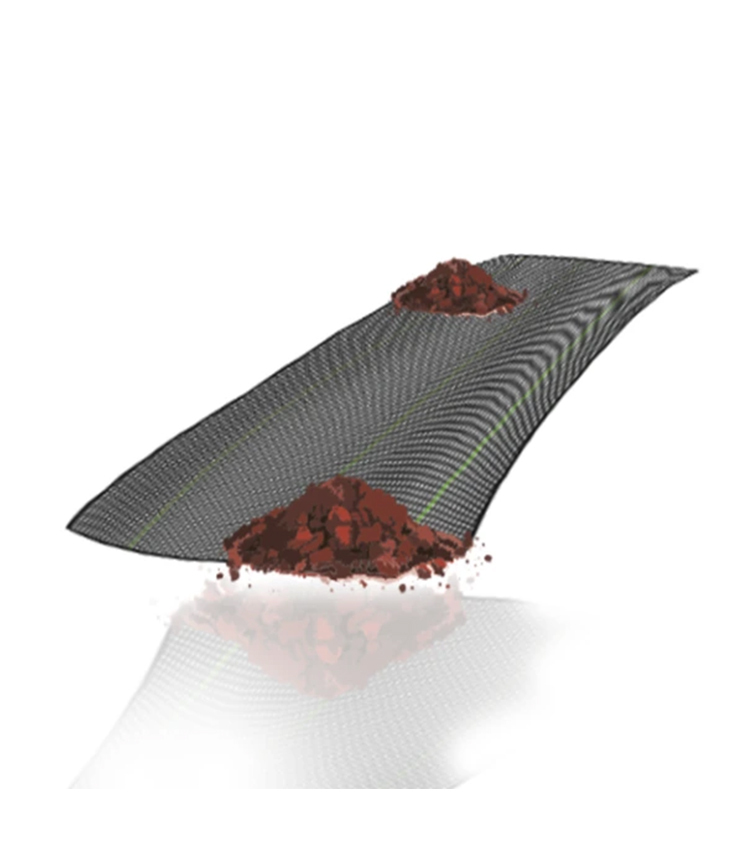

Mining operations require materials that can withstand tough conditions. Our durable bags and specialized fabrics are designed to handle tasks like sifting, separating, and transporting mined materials effectively.

The construction industry demands materials that are both robust and versatile. Our water-resistant fabrics are ideal for various applications, from reinforcing barriers to creating effective drainage systems.

- Packaging

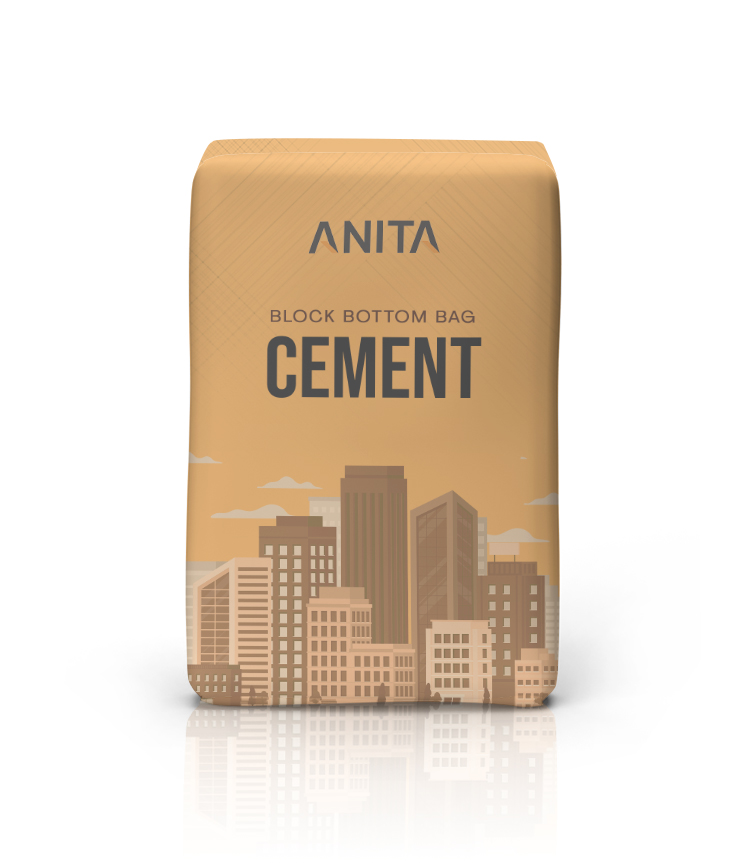

- Building Materials

- Lumber Industry

- Food Grain Storage

- Petrochemicals

- Engineering Products

- Cement Industry

- Fertilizer Manufacturing

- Transportation

- Logistics

- Animal Feed

- Industrial Products

- Mining Industry

- Retail Industry

- Food Products

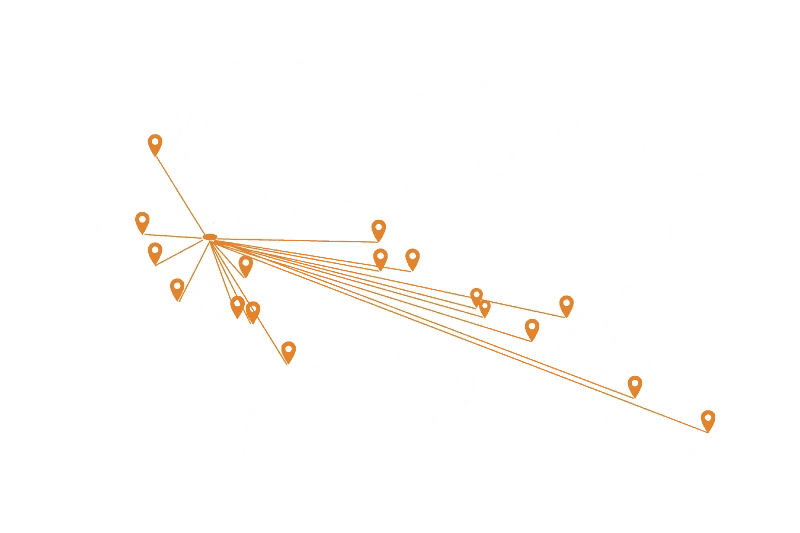

Global Reach

With our extensive global network, we can support you no matter which country you are in. We are a customer-focused company that guarantees your satisfaction!

Our Official Certifications

Featured Blogs

Beyond Packaging: How Anita Plastics Sets the Standard with FSSC and BRCGS Certifications

Introduction Anita Plastics is a beacon of excellence in the manufacturing world. It is renowned

Landscape Fabric Installation: Tips and Tricks for Beginners

What is Landscape Fabric? Landscape fabric, also known as weed control fabric, is a breathable

The Ultimate Guide to Choosing the Best Weed Barrier Fabric for Your Garden

Introduction If you’ve ever spent a sunny afternoon pulling weeds, you know how crucial it